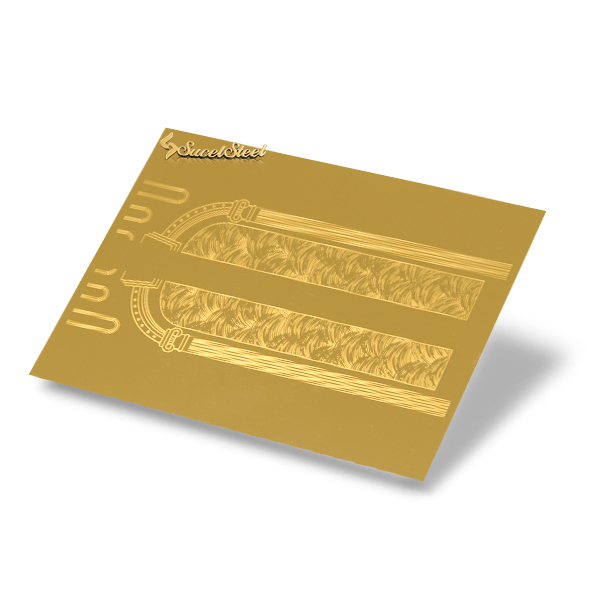

Stainless steel etched is surface processing method of making designs or pictures on the...

As we all know, stainless steel is divided into 200 series, 300 series, 400 series, such as 200 series 201, 202, 300 series 304, 316L, and 400 series 430. What is the difference between different series of stainless steel?

In stainless steel, there are two opposite forces acting simultaneously: ferrite-forming elements continue to form ferrite, and austenite-forming elements continue to form austenite. The final crystal structure depends on the relative amounts of the two types of added elements.

Chromium is a ferrite-forming element, so chromium is in a competitive relationship with austenite-forming elements in the formation of the crystal structure of stainless steel. The composition and content of different elements determine the characteristics and applications of the material.

Magnetism

430 series stainless steel is an alloy of iron, carbon, and chromium. This stainless steel has martensitic structure and iron element, so it has strong magnetic properties. SS304 is a kind of alloy material containing iron, carbon, nickel, and chromium. It has very weak magnetism in special cases, and usually default to no magnetism.

Corrosion resistance

Stainless steel has good anti-corrosion properties, and different grades of stainless steel have different anti-corrosion properties. The nickel element in 304 makes it have better corrosion resistance than SS201 and 430, and its cost is more expensive.

Malleability

Nickel not only makes 300 series stainless steel have better corrosion resistance, but its ductility is also better than 200 series, 400 series stainless steel. Therefore, in bending, welding, such processes, especially precision parts processing types, the 300 series will also be preferred. Due to the lack of nickel, 200 series and 400 series stainless steels will likely crack or break during processing.

Use

Sucel Steel commonly uses 201, 202, 304, 316L, and 430 these five types of stainless steel as material. According to different uses and budgets, Sucel Steel will recommend the most suitable substrates for processing. For example, the stainless steel plate used in the decoration industry, Sucel Steel usually uses 304, 201, 316L stainless steel. The 316L material has excellent corrosion resistance and is more suitable for the building near the beach or outdoors. For stainless steel trim, profile or channel, 304 is the best material, and its good ductility can withstand difficult processing, such as bending, laser cutting, welding, etc., Such as the production of T6 profiles, the failure risk of using 201 material is 3-4 times higher than that of 304. In the magnetic industry, there is no doubt that 430 material is the only choice. Sucel Steel can produce products with different shapes and different color surfaces according to customer needs.

Stainless steel etched is surface processing method of making designs or pictures on the...

Stainless steel sheets are a popular material choice due to their durability, corrosion resis...

CabinetReception RoomWindow Frame Hello, this is our custom decoration of an upscale hotel. Th...

First of all, our exhibition this perfect end, a lot of decor stainless steel products, are liked by...

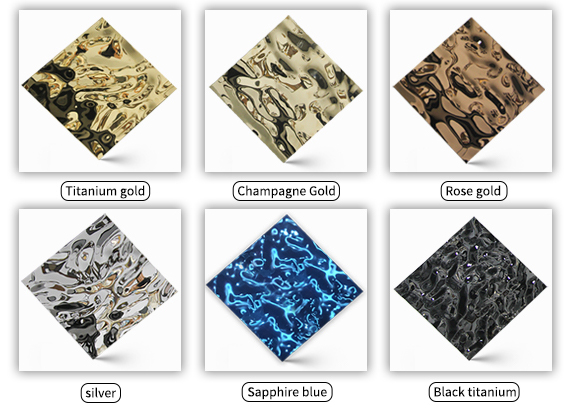

The water ripple stainless steel sheet is mainly made by stamping the pattern on the stainles...

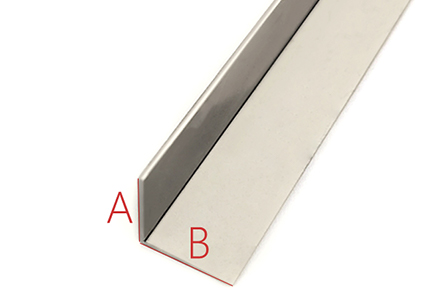

In the size selection of stainless steel profiles, in order to provide you with better service, we n...